nasa MICHOUD ASSEMBLY FACILITY cryogenic storage

Date: June - August 2024

Location: NASA Michoud Assembly Facility (MAF) - New Orleans, LA

Client: NASA

NASA’s rocket manufacturing facility in East New Orleans consumes hundreds of gallons of liquid nitrogen per week, almost all of which is converted to gaseous nitrogen to feed the 830-acre industrial complex. The source of the nitrogen is stored as a -320°F liquid inside three cryogenic pressure vessels. Each is approximately 500 gallons in volume. Critical to their low-temperature storage ability is the vacuum insulation contained by larger vessels encasing the liquid tanks.

After more than 30 years of service and exposure to the outside elements, widespread pitting corrosion began threatening the vacuum retaining integrity of the carbon steel outer jackets. NASA funded a major refurbishment project to rehabilitate the entire cryogenic conversion facility at MAF, including all three liquid nitrogen vessels. In tandem with the construction contractor weld repairing widespread lost metal, our inspection personnel served as NASA’s Quality Assurance representative. C3 provided necessary protective coating inspection to ensure the integrity of the recoat system and mitigate future corrosion concerns for these critical NASA assets.

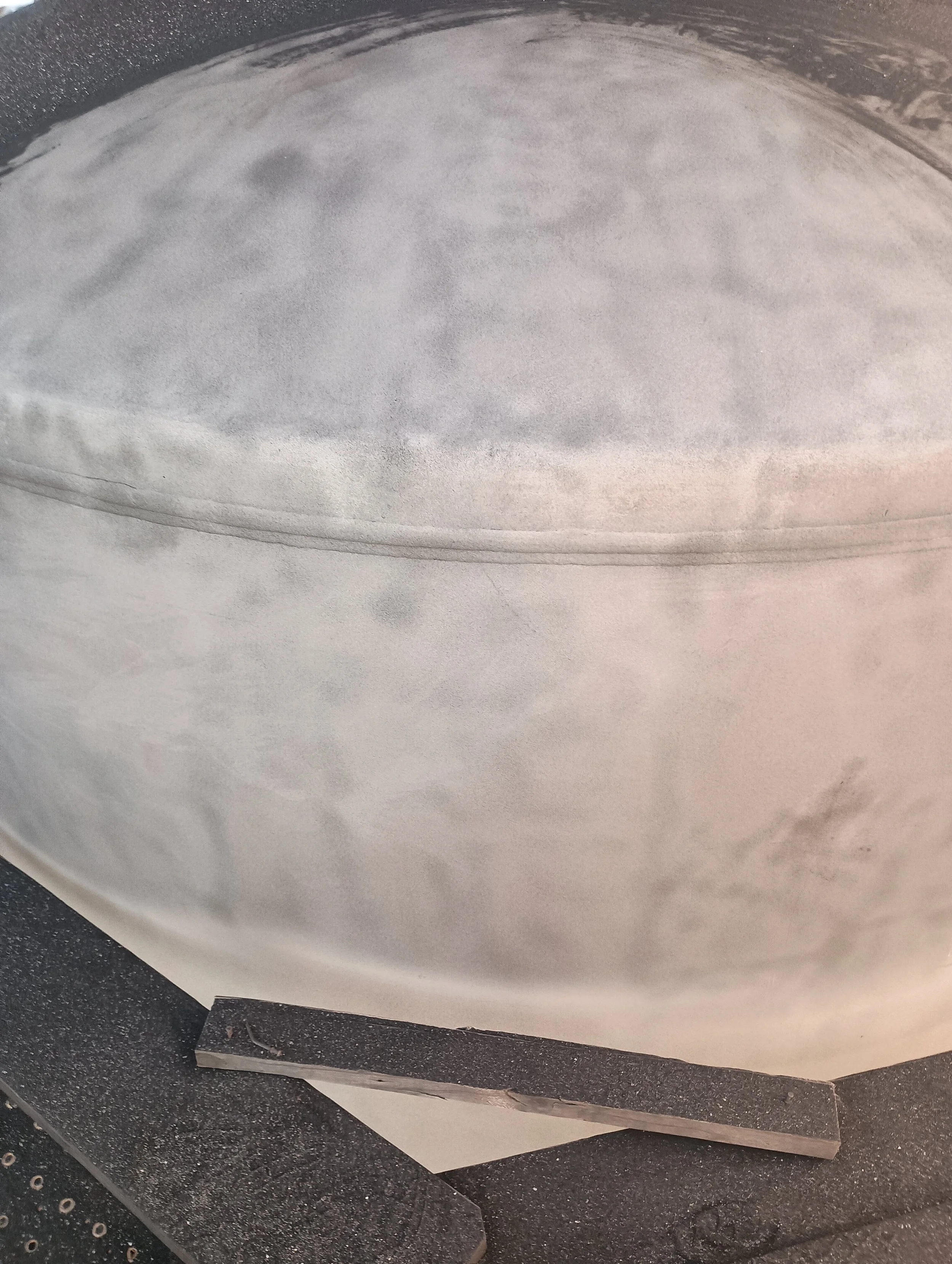

Top coat applied to liquid nitrogen tanks

BEFORE

Two of three liquid nitrogen tanks

to be repaired and recoated

Top of the tank

Close up of one of the leg supports for one tank. Several years of trapped moisture gave rise to severe corrosion

Blasted surface of the tank before painting

AFTER

Recoated support leg

Top coat applied to liquid nitrogen tanks